Trust in quality! fujian Nonnon technology fine grade sand aggregate production line used in Ningbo Yongke, Ningbo Nanwan.

Release Time:

2021-09-15

Non-metallic mineral materials fine processing technology and equipment professional operators

New technology, new equipment, make materials more valuable!

With the rapid development of the national economy, the rapid growth of various infrastructure, industrial and civil buildings, and the rapid development of highways, high-speed railways and municipal projects, there is no effective substitute for sand and gravel as an important engineering raw material. the sharp increase in its use and the continuous improvement of quality requirements have obviously promoted the rapid and high-quality development of the industry.

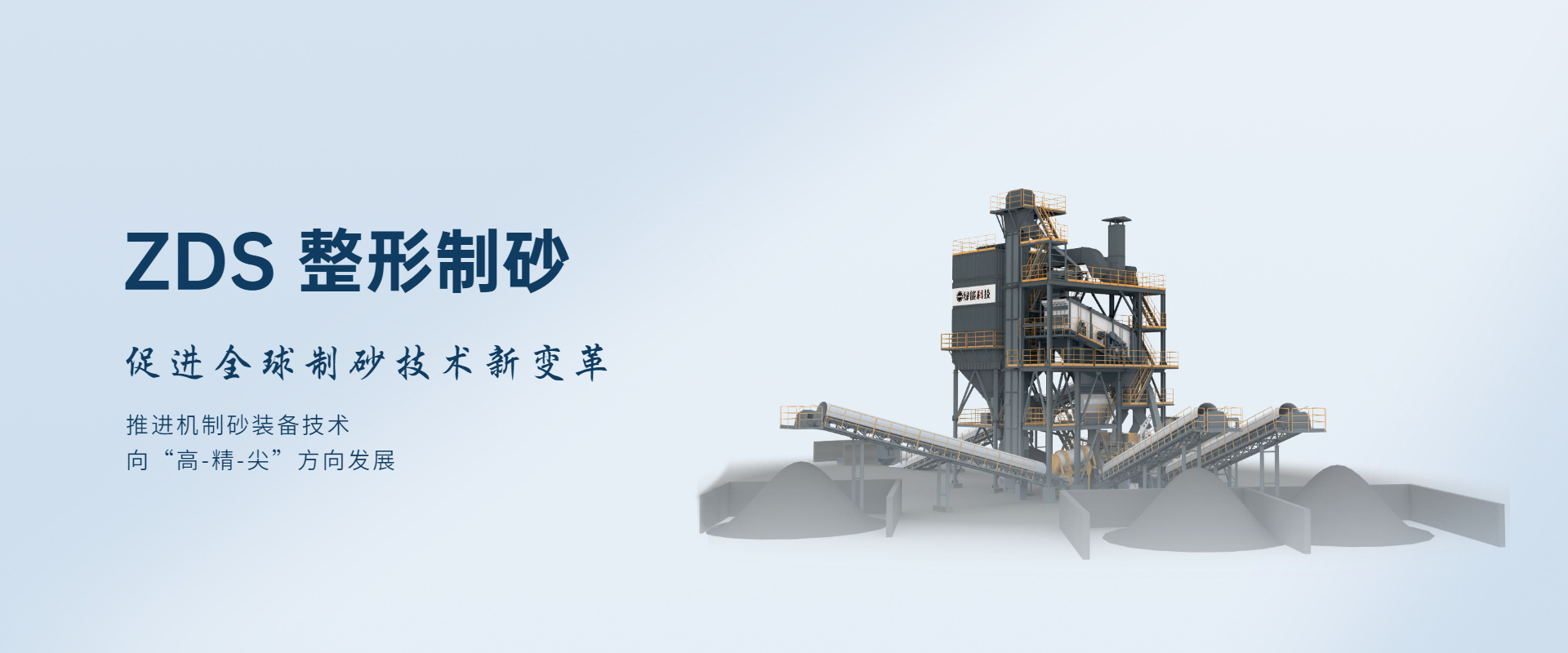

AsHigh-end non-metallic mineral set (powder) technical equipment professional operators, products related:Fine gravel aggregate, kaolin crushing and screening, gypsum crushing, graphite and shale fine crushing equipment. The high-quality graded sand and gravel production equipment manufactured by Green Energy Technology is favored by customers because of its large output, fast and adjustable grading, high crushing efficiency, low energy consumption, low wear, excellent environmental protection indicators, high reliability, and good grain shape of products.

Project Background

As a pilot city of a powerful transportation country, Ningbo is one of the national pilot tasks to improve the industrialization level of transportation engineering. In this process, the Municipal Transportation Bureau and the Municipal Transportation Engineering Center actively guide construction and construction units to use digitalization and mechanization to improve management efficiency and improve Project quality.

At present, Ningbo has cultivated and built 9 industrial production bases, including 2 prefabricated component manufacturing bases, 4 asphalt comprehensive industrial bases,2 fine sand and gravel aggregate manufacturing base1. A production line for resource disposal of residue and mud. The products produced are applied in some key highway and water transportation projects in Ningbo, which promotes the industrialization and transformation of traffic engineering.

Ningbo Yongke Transportation Industry Company and Ningbo Nanwan Transportation Development Co., Ltd. are companies under Ningbo Jiaotong Group, which have R & D centers, automated production lines, trinity pavement factories and supporting facilities. From a distance, the huge "super factory" is full of modern feeling.

The raw material of the project is tuff, with compressive strength as high as 200 MPa, silica content of 60%, high abrasiveness and density, and extremely difficult to break.Ningbo Yongke Transportation Industry Company and Ningbo Nanwan Transportation Development Co., Ltd. set up tenders in September 2022 and January 2021 respectively to purchase complete sets of tower-type plastic sand making equipment. After comprehensive analysis of the specific needs of customers, Green Energy Technology Technical Engineers quickly issued a process plan. All indexes were better than the bidding requirements. They beat many other competing manufacturers with strength and quality and finally reached cooperation with customers.

Ningbo Yongke Project Successfully Put Into Operation

Project smoothly put into production

After the customer purchased the green energy technology equipment, it was put into production and operation as soon as possible. At present, the equipment operates for an average of 20 hours a day. In addition, according to different crushing requirements, the equipment can flexibly adjust the production process. when the feeding is 5~40mm and the fineness modulus is 2.8, the output of manufactured sand products is> 100 T/h; When the feeding is 5~40mm and the sand and gravel are produced together, the total output of plastic gravel and manufactured sand products is> 300 t/h, and the finished products are: 0-4.75mm,4.75-10,10-20-20-31.5mm, it can also be applied to the production of high-grade asphalt graded aggregates, with a total of five aggregates. The economic benefits are considerable. At the same time, it has made excellent graded gravel and standard sand, and the gradation is adjustable, and the output is guaranteed, which has been highly recognized by customers!

Ningbo Nanwan Project Site

Process description and process innovation:

Fujian Green Energy Environmental Protection Technology Sand Building is a highly integrated tower-type fully enclosed structure, using a dry sand production system. The entire closed-loop control system is based on automatic control of fineness modulus and powder content as the core technology. The entire sand production process is completed on the same sand tower, which reduces a large amount of floor space, and also simplifies a part of the production process, with lower maintenance rate and higher efficiency.

Optimize shaping! Efficient sand making! Gradation adjustment! Stone powder control! Humidity control! Environmental protection dust!

The specific scope of supply of this project: from the feeding belt (with frequency conversion metering) to the discharging belt (including sand making and shaping machine, grading adjustment machine, belt conveyor conveying equipment, bucket elevator equipment, screening equipment, air separation equipment, humidifier, dust collector, stone powder proportion adjustment device, gravel surface powder removal device, frequency conversion induced draft fan) and a full set of parts, non-standard parts, pipelines, electric control equipment and systems, and steel structures until stone powder is stored.

This process adopts the double sand machine production process, for our company.Invention patent (Fujian Province first set of honor)It is much better than the traditional single machine production process. In order to achieve the output of sand, the traditional process generally uses a large host, which has the disadvantages of low sand production rate, poor gradation and high energy consumption. Green Energy Technology adopts dual main machines. The two main machines have different linear speeds, different rotor flow channels and projection trajectories, and different crushing cavity linings, which are more conducive to the crushing of materials between 2.36mm and 16mm, to the satisfaction of gravel gradation and grain type. The output rate is generally higher than 15% of peers, and the energy consumption is lower.

ZDS shaping sand making adds the function of shaping on the basis of DS pure sand making, which makes the sand and gravel more beautiful at the same time. Moreover, a plurality of discharge belts can produce sand and gravel of different specifications, which can more closely meet the needs of customers.

Related News

undefined

Tik Tok

Fujian Green Energy Environmental Protection Technology Co., Ltd.

Service Hotline:4006655896

Tel:0595-22557155、13808548004

Email:nonnon@fjlnkj.com

Website:http://www.fjlnkj.com/

Factory Address: Hardware and Electromechanical Industrial Park, Luojiang Economic Development Zone, Quanzhou City, Fujian Province (No. 268, Luobin North Road)

Page Copyright © 2022 Fujian Green Energy Environmental Protection Technology Co., Ltd.