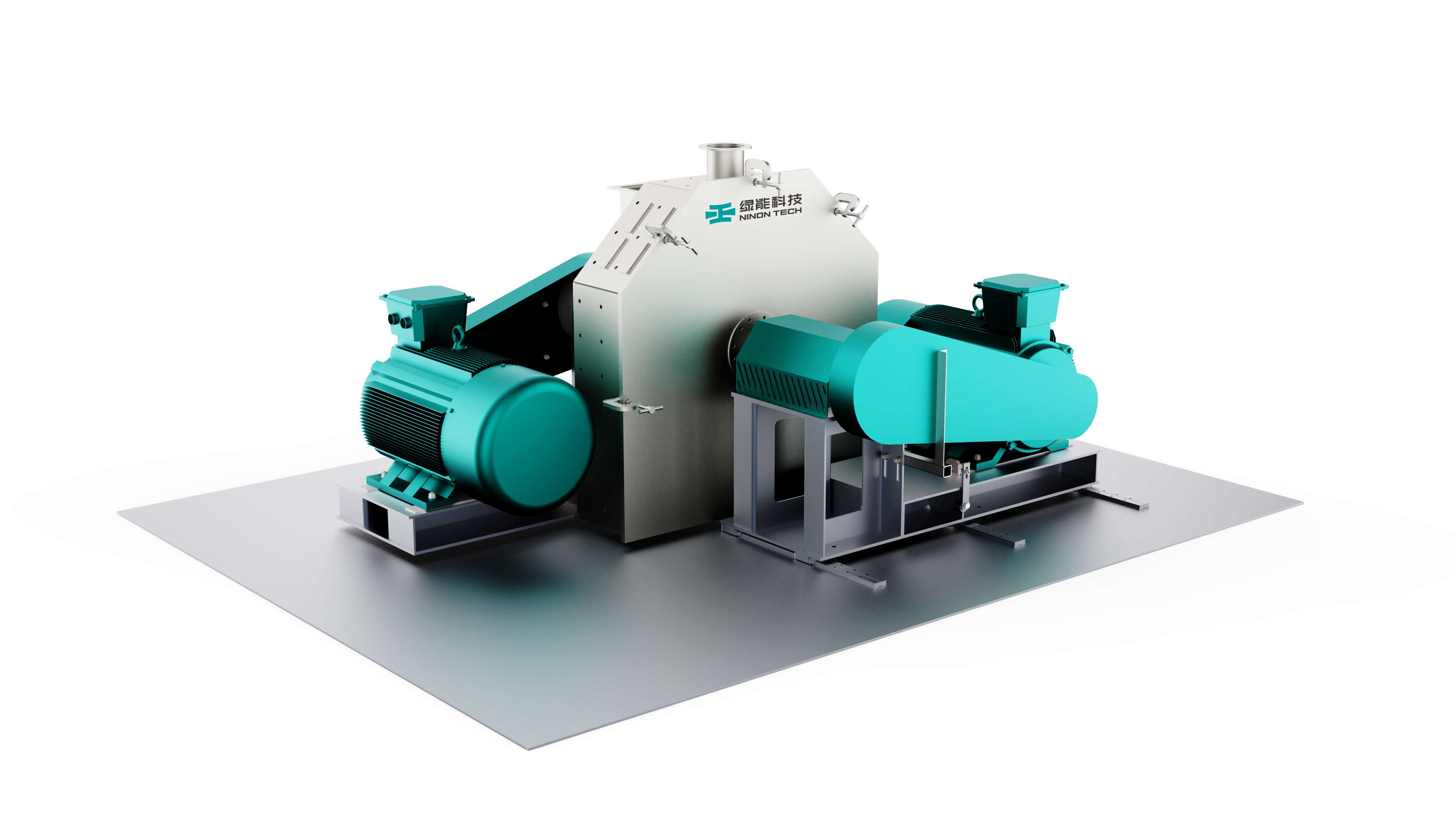

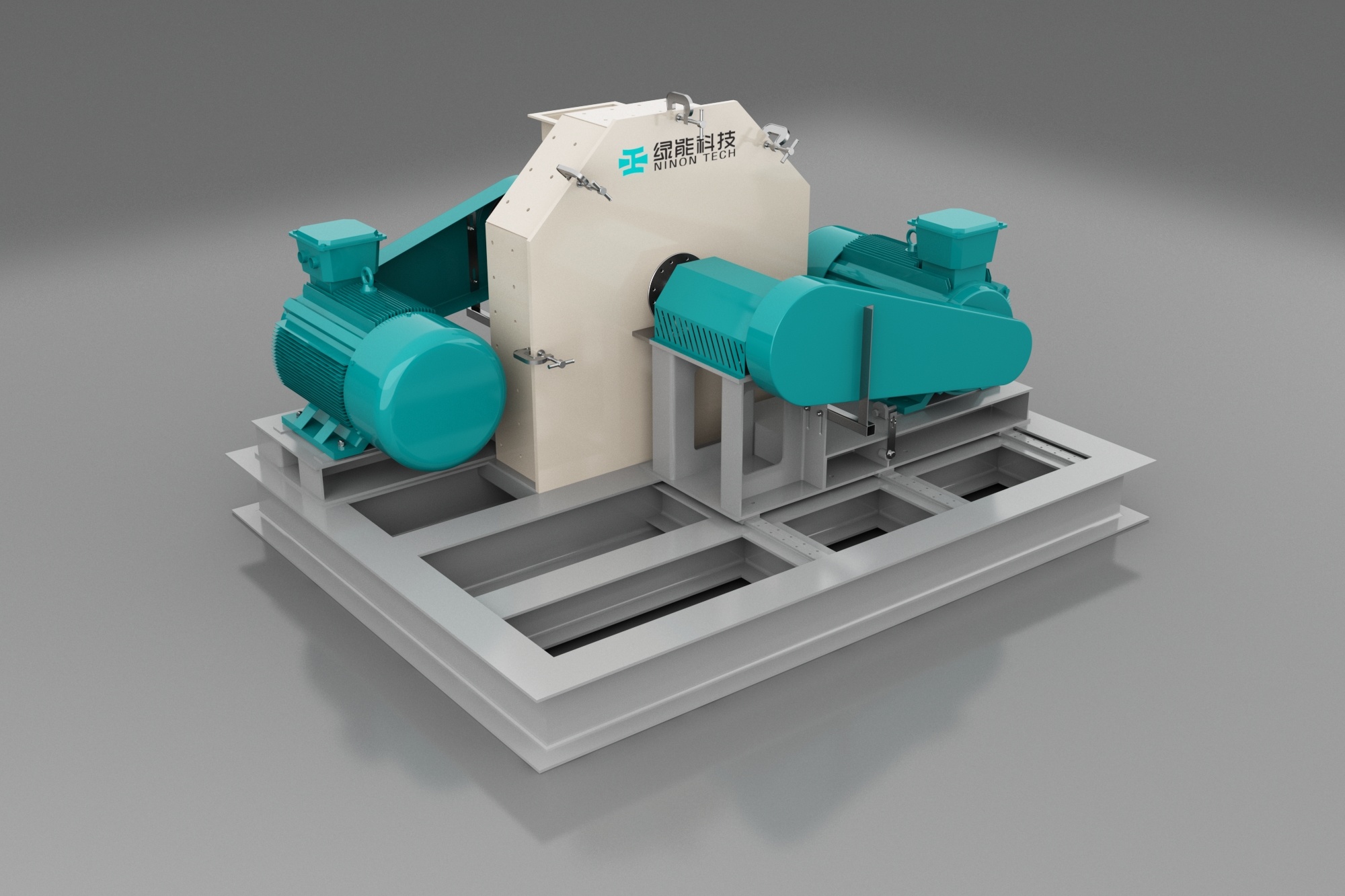

HCC(s) consultation grinding /fine crushing machine

Keyword:

Tel:

Email:

Category:

HCC(s) consultation grinding /fine crushing machine

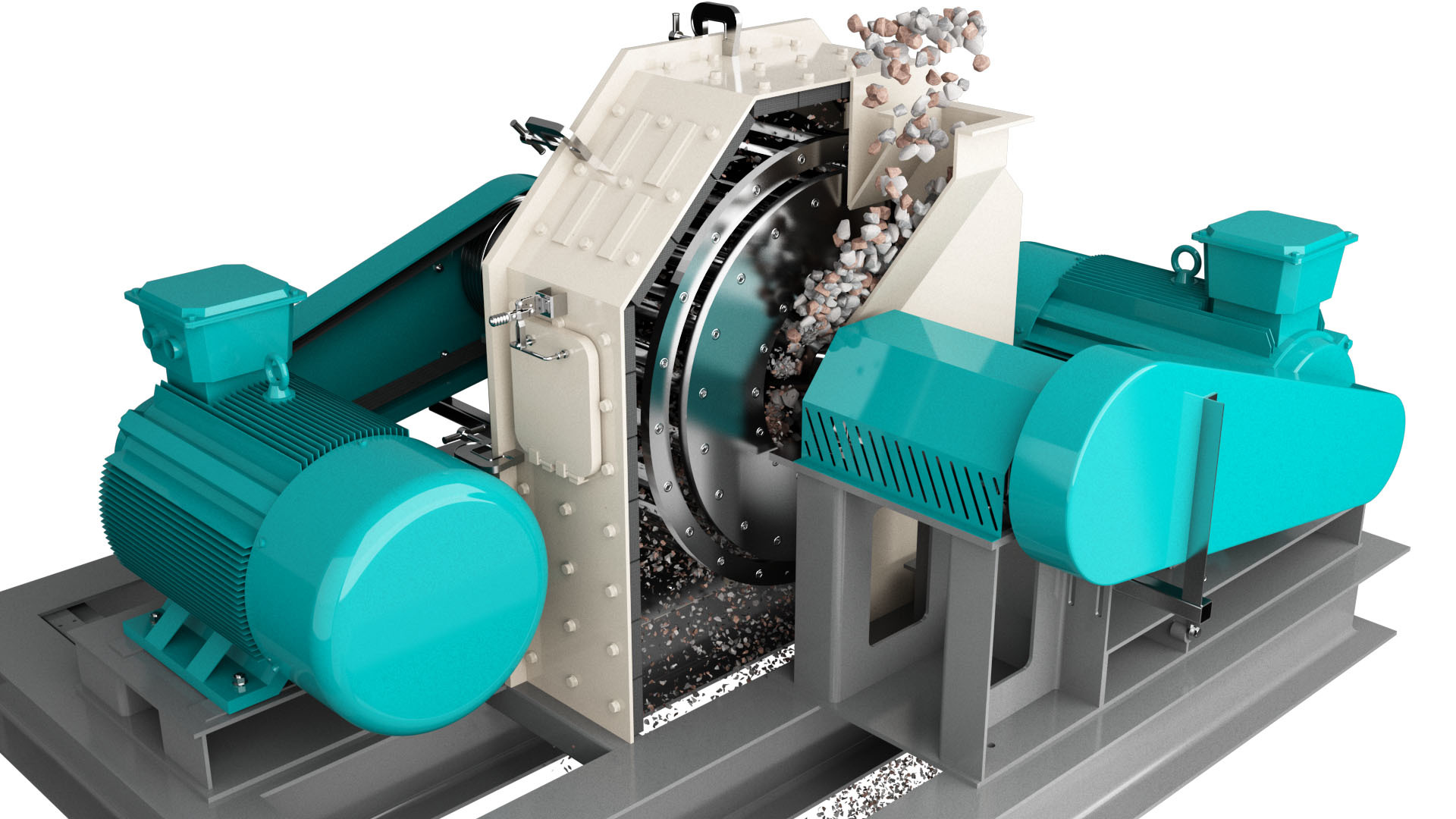

This machine isIndustry first, the use of shearing, grinding-based, moderate flexible percussion technology as a whole, the recycled materials for composite processing, removal of asphalt, reduce crushing. It can be adjusted by adjusting the frequency, the spacing between the grinding rods, the shape of the grinding rods (quadrangular, hexagonal, prismatic, comb-shaped), the material of the grinding rods, the diameter, the number of cages (2-6) and other means.If the RAP original material is better, it can be directly sheared to break up and classify without crushing.

Features and advantages:

HCC is a leading and innovative technical product in the industry. It uses the principles of centrifugal ejection and return of materials for multiple impacts, grinding and shearing to crush material particles to the required fineness, 240 a crushing ratio of: 1 and above and high consistency of discharge particle size, which is superior to most other crushers. Therefore, it has lower energy consumption, with energy consumption per ton of about 1.5 to 5KW. This machine is particularly suitable for making fine moist and viscous materials. The HCC pulverizer is likely to reduce the traditional two-stage process to a single-stage pulverization process. HCC can be crushed, ground, abrasive and non-abrasive including wet. sticky or dry various materials.Selective impact crushing is a core feature of HCC shredders.

HCC is generally used as medium and fine crushing, with a maximum feed particle size of 100mm and a minimum feed particle size of 10mm. It is recommended that the optimal feed particle size is 10-80mm, the medium and fine crushing finished products are generally less than 05mm, and the fine crushing finished products are generally 0-1mm or less, which can produce 85% of -200 mesh products at most. Optional with heating drying and airflow classification device.

|

Model |

Power (KW) |

Number of ring cages (pcs)

|

Bar shape |

form of control |

Feed particle size (mm) |

Handling capacity (t/h) |

Basic configuration |

Application areas |

|

HCC1200 |

55 75 |

2/4/6 |

Multiple |

double frequency conversion |

<30 |

35-45 |

Non-standard |

Dry and wet materials finely crushed, recycled aggregate depolymerization |

|

HCC1400 |

75 90 |

2/4/6 |

Multiple |

double frequency conversion |

<40 |

45-70 |

Non-standard |

|

|

HCC1600 |

90 110 |

2/4/6 |

Multiple |

double frequency conversion |

<50 |

70-120 |

Non-standard |

|

|

…… |

|

|

|

|

|

|

|

Remarks:1: The bar shape is divided into four types: round, square, hexagonal, comb type2: The mechanism and parameters vary depending on the crushed material.2: Moisture content:0-6%(Based on plasticity and viscosity indicators)3Adaptation: Mohs hardness≤6

4Not suitable for: heat sensitive and volatile toxic materials, flammable and explosive materials

Application: Recycled aggregate depolymerization surface strengthening, mineral material fine grinding powder (8-400 mesh)

Related Products

undefined

Product Message

Tik Tok

Fujian Green Energy Environmental Protection Technology Co., Ltd.

Service Hotline:4006655896

Tel:0595-22557155、13808548004

Email:nonnon@fjlnkj.com

Website:http://www.fjlnkj.com/

Factory Address: Hardware and Electromechanical Industrial Park, Luojiang Economic Development Zone, Quanzhou City, Fujian Province (No. 268, Luobin North Road)

Page Copyright © 2022 Fujian Green Energy Environmental Protection Technology Co., Ltd.