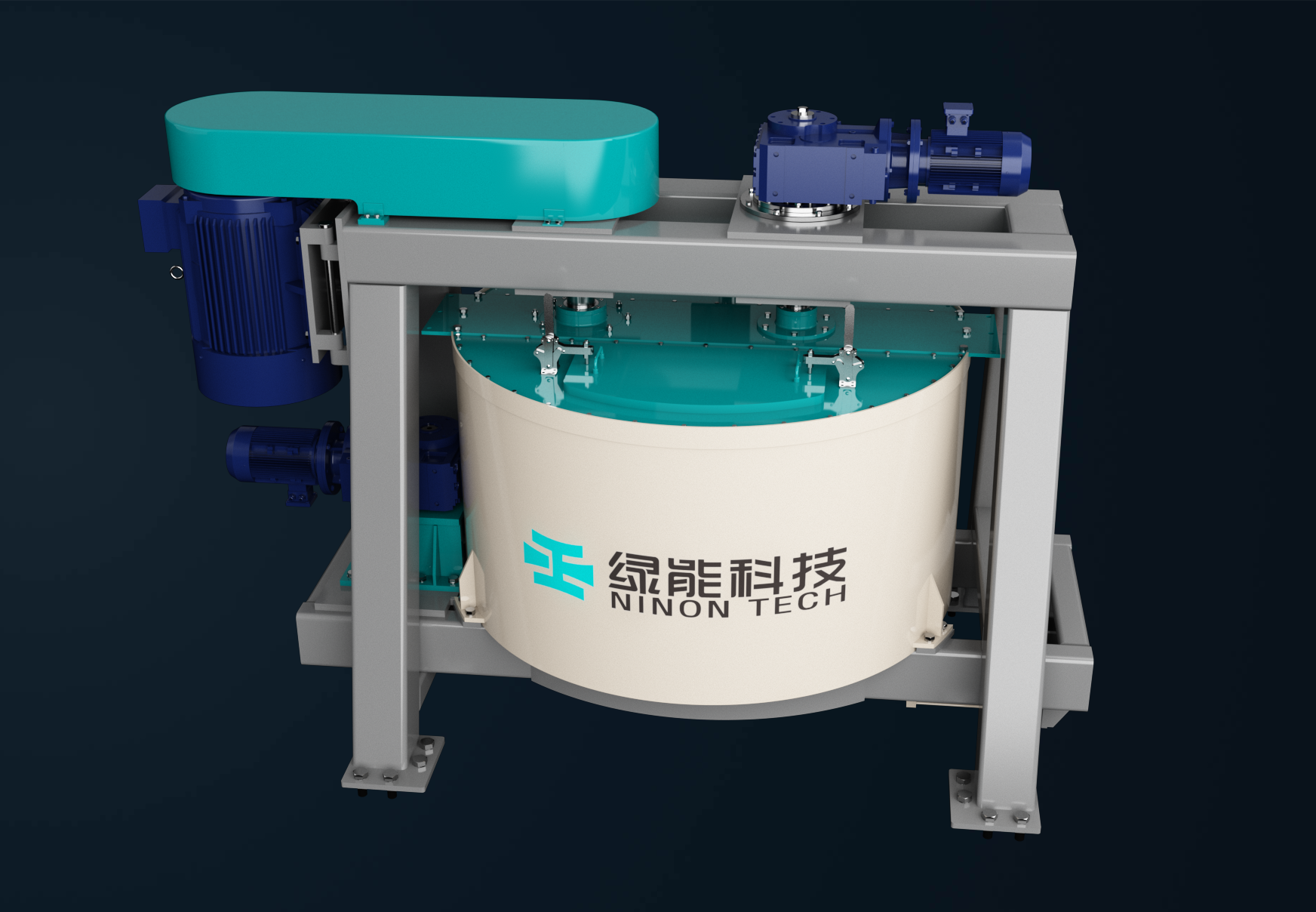

CSM three-dimensional shear countercurrent type mineral material mixing mixer

Keyword:

Tel:

Email:

Category:

CSM three-dimensional shear countercurrent type mineral material mixing mixer

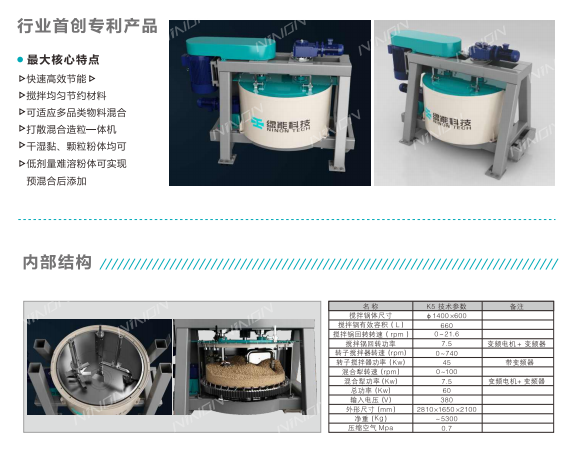

| Model | LNK5(650/950) | LNK6(1350/2000) | LNK7(2000/3000) | Remarks | |

| 1 | Stirring pot body size (mm) | φ 1400 × 600 | φ 1800 × 800 | φ 2000 × 950 | |

| 2 | Stirring volume (L) | 630 | 1350 | 2000 | |

| 3 | Power of stirring pot (Kw) | 5.5~11 | 7.5~15 | 11~22 | frequency converter variable frequency motor |

| 4 | Stirring pot speed (rpm) | 0~13 | 0~13 | 0~13 | |

| 5 | High shear mixer power (Kw) | 22~45 | 30~55 | 30~75 | frequency converter variable frequency motor |

| 6 | High Shear Agitator Speed (rpm) | 0~740 | 0~740 | 0~740 | |

| 7 | Hybrid plough power (Kw) | 7.5~15 | 11~22 | 11~30 | frequency converter variable frequency motor |

| 8 | Mixing plough speed (rpm) | 0~34 | 0~34 | 0~34 | |

| 9 | Compressed air Mpa | 0.7 | 0.7 | 0.7 | |

| 10 | Overall dimension (mm) | ~ 2810 × 1650 × 2150 | ~ 3300 × 2100 × 2430 | ~ 3550 × 2300 × 2600 | |

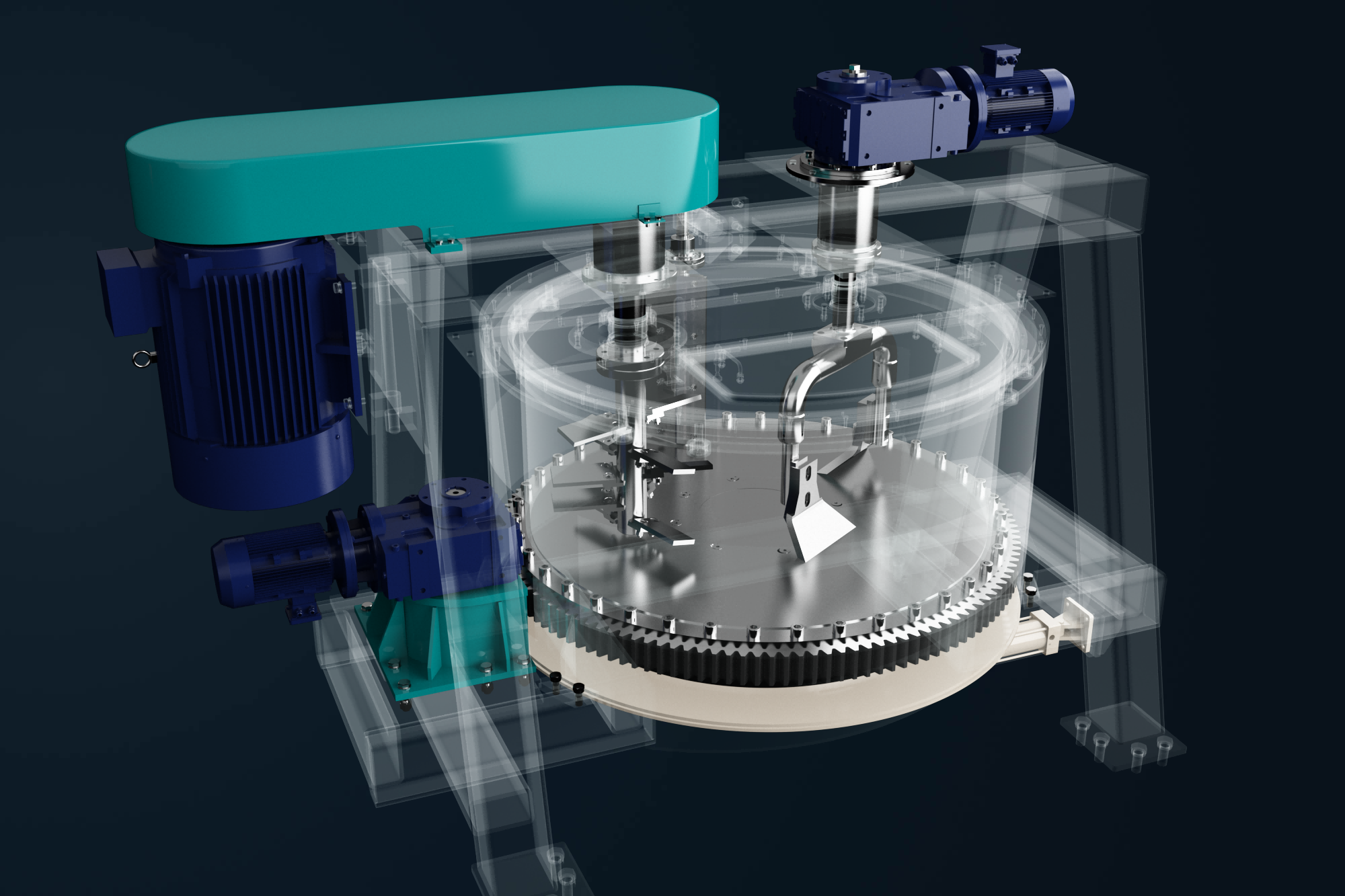

| 11 | Configuration (including optional) | High-shear mixer, needle-type granulation mixer, pear-knife combination, side wall scraper, rotating high-pressure cleaning nozzle, turbine pre-shear mixing pump, temperature sensor, two-stroke variable-track cylinder discharge door | |||

| 12 | Application field | UHPC, SCC, GFRC, powder concrete, rock plate, real stone paint, ceramics, polymer functional mortar, glass, refractory materials and waste slag powder, silt recycling and other industries mixing and granulation. | |||

| 13 | Note 1: This machine is suitable for dry and wet mixing of small particle size materials. 2: The structure and parameters are different according to the mixing material. | ||||

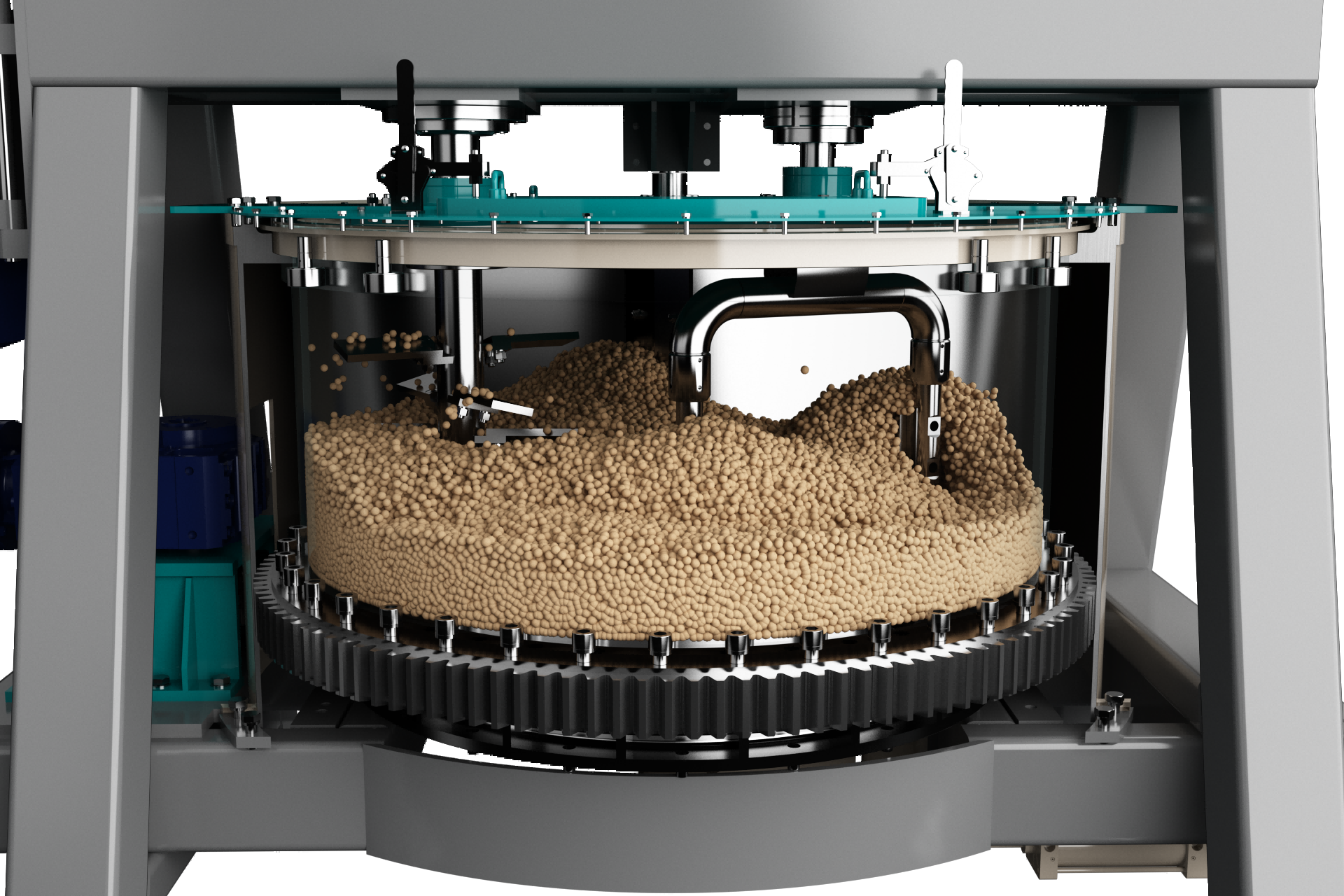

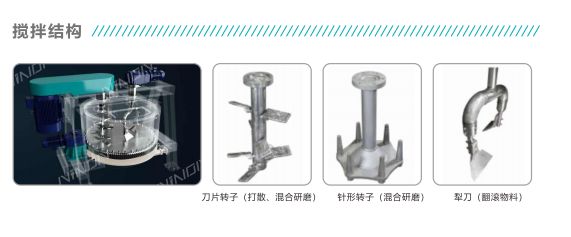

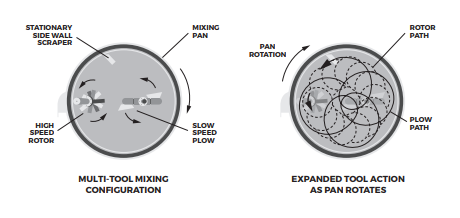

Principle:Used in high-shear continuous mixing and granulation, the mixing process adopts three-dimensional counter-current mixing technology design (high-speed blade shear to break up the material, low-speed pear knife to turn over the material plate and reverse roll the material), which can improve mixing uniformity, shorten mixing time and improve mixing granulation performance.

Bulk materials that can be mixed and granulated in various industries such as high-performance building materials, ceramics, fertilizers, glass, refractory materials and waste recycling.

A high shear mixer is ideal for processing a variety of high-quality construction materials, such as dry mortar, grout, concrete, special concrete products, clay and lightweight construction aggregates.

Important knowledge points of mixing and stirring

The preceding description deals with some basic energy-related considerations in mixing:

1. A certain minimum strength level is required to achieve good mixing. The minimum intensity level depends on the characteristics of the components and their interactions.

2. A fixed amount of energy is required to disperse equal amounts of ingredients with the same characteristics to the same degree of uniformity.

3. The mixing energy should be evenly distributed to the batch.

4. Mixing time and intensity are inversely related by mixing energy

5. The full dispersion of fine particles or powder and uniform spreading are the key factors, which can ensure the rapid and uniform mixing of materials.

Thus, in general, if the specific strength (I. e. the strength per unit weight of the mixture) is doubled, the mixing time to reach the same level of dispersion can be halved, which is not a great revelation.

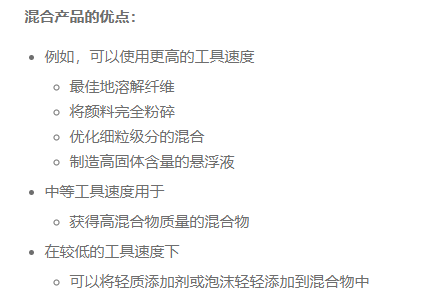

For batch processing, the intensity can be controlled by adding/removing mixing tools, or the speed of mixing tools can be increased, or both. Velocity approximations generally follow the relationship of intensity as a function of the square of tool velocity. For example, doubling the peripheral speed of the stirrer will increase the stirring intensity by four times, resulting in a reduction of the mixing time to 1/4. Suddenly, the capacity of the same mixer almost quadrupled!

High shear mixer-main application industry

1, precision casting industry-sand mixing, reclaimed sand homogenization.

2. Metallurgical industry-powder alloy

3, the automotive industry-friction materials.

4. Utilization of clay refractories and metal tailings slag powder

5, Precision, ordinary ceramic materials

6. High performance concrete UHPC, mortar

7, Kaolin porcelain clay industry

8, Imitation stone paint, artificial stone, rock plate industry

9. New energy battery materials

10 Other industries

Related Products

undefined

Product Message

Tik Tok

Fujian Green Energy Environmental Protection Technology Co., Ltd.

Service Hotline:4006655896

Tel:0595-22557155、13808548004

Email:nonnon@fjlnkj.com

Website:http://www.fjlnkj.com/

Factory Address: Hardware and Electromechanical Industrial Park, Luojiang Economic Development Zone, Quanzhou City, Fujian Province (No. 268, Luobin North Road)

Page Copyright © 2022 Fujian Green Energy Environmental Protection Technology Co., Ltd.