HMW intelligent mineral fine material stirring and scrubbing machine

Keyword:

Tel:

Email:

Category:

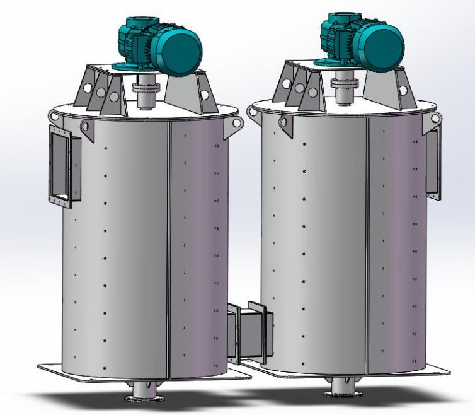

HMW intelligent mineral fine material stirring and scrubbing machine

HMW scrub machine is a high concentration of strong stirring scrub beneficiation equipment, can solve the generalDrum screen, Ferris wheel, spiral washWashing requirements that cannot be completed (wash not clean), mainly used for the dispersion of viscous and dirty slimes, the removal of impurities (soil, light substances, oxides) on the mineral surface, especially suitable for the scrubbing of fine mineral materials (quartz sand, kaolin, lithium ore soil, ceramic soil, precision casting sand, metal minerals, etc.) to improve the quality of materials. The highly efficient stirring scrubbing machine can scrub and purify various loose mud plasmid structure minerals or materials and disperse and dissociate mud materials. Can effectively remove the glue attached to the mineral surface of the solvent and soil, which has the characteristics of impact resistance, corrosion resistance, long service life and low failure rate.

Applicable industry: fracturing sand quartz sand kaolin construction waste other mineral washing and impurity removal (moderate light material selection)

Principle of HMW equipment;

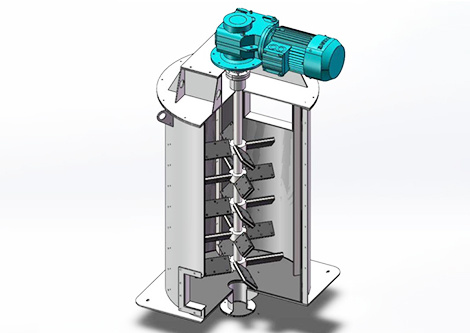

When the agitator is installed along the center line of the container, the viscosity of the stirring material is not large, and the stirring speed is high, the liquid will move together with the rotation direction of the prize leaf, the liquid in the middle part of the container will rush to the inner wall and rise under the action of centrifugal force, and the liquid level in the center part will drop, forming a vortex, which is usually called "swimming area". With the increase of the stirring speed, the center of the vortex is concave to contact with the prize blade. At this time, the outside air enters the blade and is sucked into the liquid. After the liquid is mixed with the gas, the density decreases, thus reducing the mixing effect. In order to eliminate this phenomenon, a certain number of baffles can usually be added. The baffle installed in the cylinder can change the tangential flow of the rotation into radial and axial flow, which greatly increases the shear strength of the fluid and improves the stirring effect from the surface. Therefore, the baffle is mainly set to eliminate the vortex, improve the circulation of the main body, increase the degree of expansion, improve the stirring effect, and at the same time reduce the fluctuation of the stirring load, so that the power consumption remains stable.

The structure and number of baffles have a great influence on the mixing effect. Too many baffles will reduce the flow of fluid within the vessel, limiting mixing to localized areas, resulting in poor mixing performance. In general, 4 baffles with a width of 1/12~1/10 of the diameter of the container are evenly installed on the inner wall surface of the container, which can meet the full baffle condition (if the number of baffles and the width of the baffle are increased, the power consumption will no longer increase).

HMW working principle:

The slurry enters the cavity of the scrubbing machine through the feed pipe, and under the powerful stirring action of the impeller, the slurry produces violent turbulence and vortex boiling. The mineral grains have huge momentum in them and produce violent friction and collision with each other. The impurity film wrapped in the surface of the mineral grain is easy to be stripped off the mineral surface after friction and impact due to its low strength. The cement on the mineral surface is soaked in water and then through the strong friction and collision between the mineral particles, it will also be loose and broken, so as to achieve the separation of clay and mineral particles. These film impurities and clay are broken and peeled off into the pulp, which can be separated from the pulp after subsequent desliming. Pulse compressed air device can be installed at the bottom or installed as requiredPulsediaphragm valve, sprayed into a liquid to produceSurgeor"cavitation"phenomenon, to achieve better washing effect andModerate light substance removal effect.

HMW Instructions for Use

The retention time of the material in the scrubbing unit is preferably between one and eight minutes. Longer residence time may lead to a diminishing return on energy consumption and capital investment to achieve the best washing effect, the feed particle size should be <10mm, and the pulp concentration should be between 65% and 75% (depending on the mineral characteristics, generally considering viscosity and surface dirt characteristics). Generally, it is placed at the end of the process for fine washing and connecting with dehydrating screen and mud concentration device.

This equipment has intelligent features:

It can be equipped with variable frequency speed regulation, main current monitoring, stirring shaft lifting adjustment, pulp concentration online detection device. According to the stirring current, the concentration and speed of the slurry are intelligently and automatically adjusted to achieve the best scrub effect. Different materials, mixing blade number and installation angle, blade shape can be adjusted according to different materials.

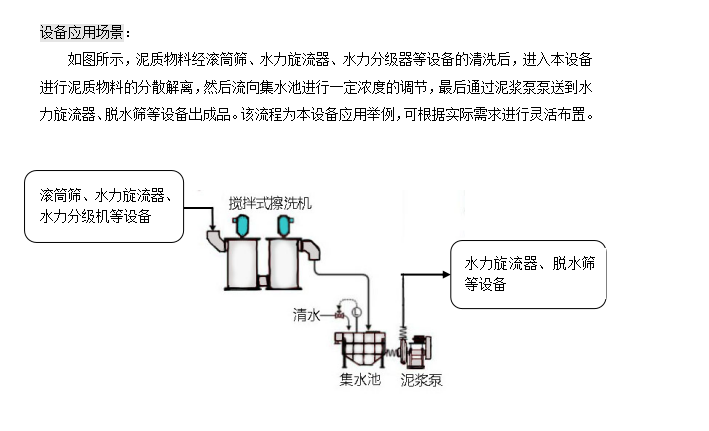

General process flow

Related Products

undefined

Product Message

Tik Tok

Fujian Green Energy Environmental Protection Technology Co., Ltd.

Service Hotline:4006655896

Tel:0595-22557155、13808548004

Email:nonnon@fjlnkj.com

Website:http://www.fjlnkj.com/

Factory Address: Hardware and Electromechanical Industrial Park, Luojiang Economic Development Zone, Quanzhou City, Fujian Province (No. 268, Luobin North Road)

Page Copyright © 2022 Fujian Green Energy Environmental Protection Technology Co., Ltd.