Fine sand crushing and grading plant

Keyword:

Tel:

Email:

Category:

Fine sand crushing and grading plant

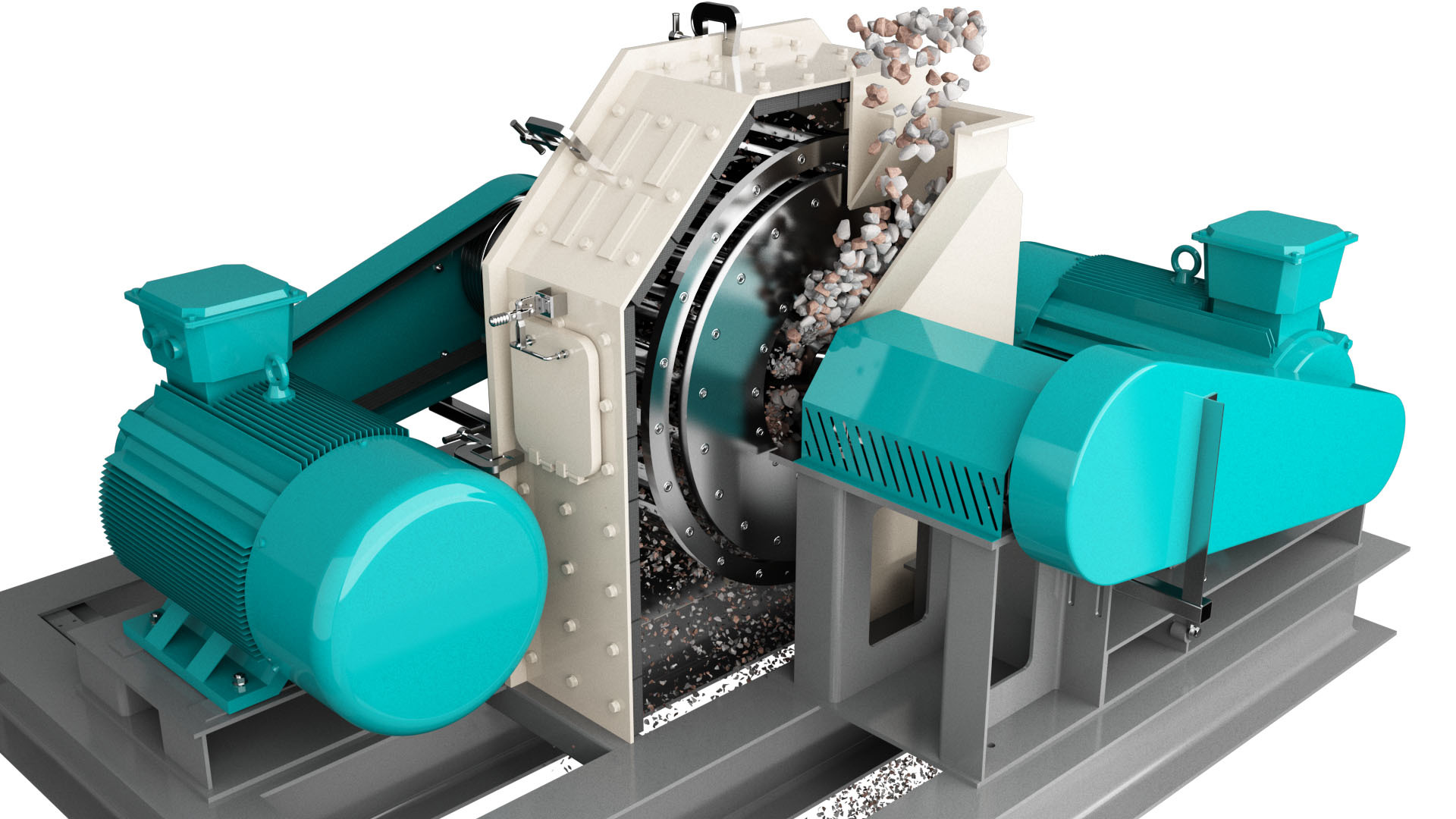

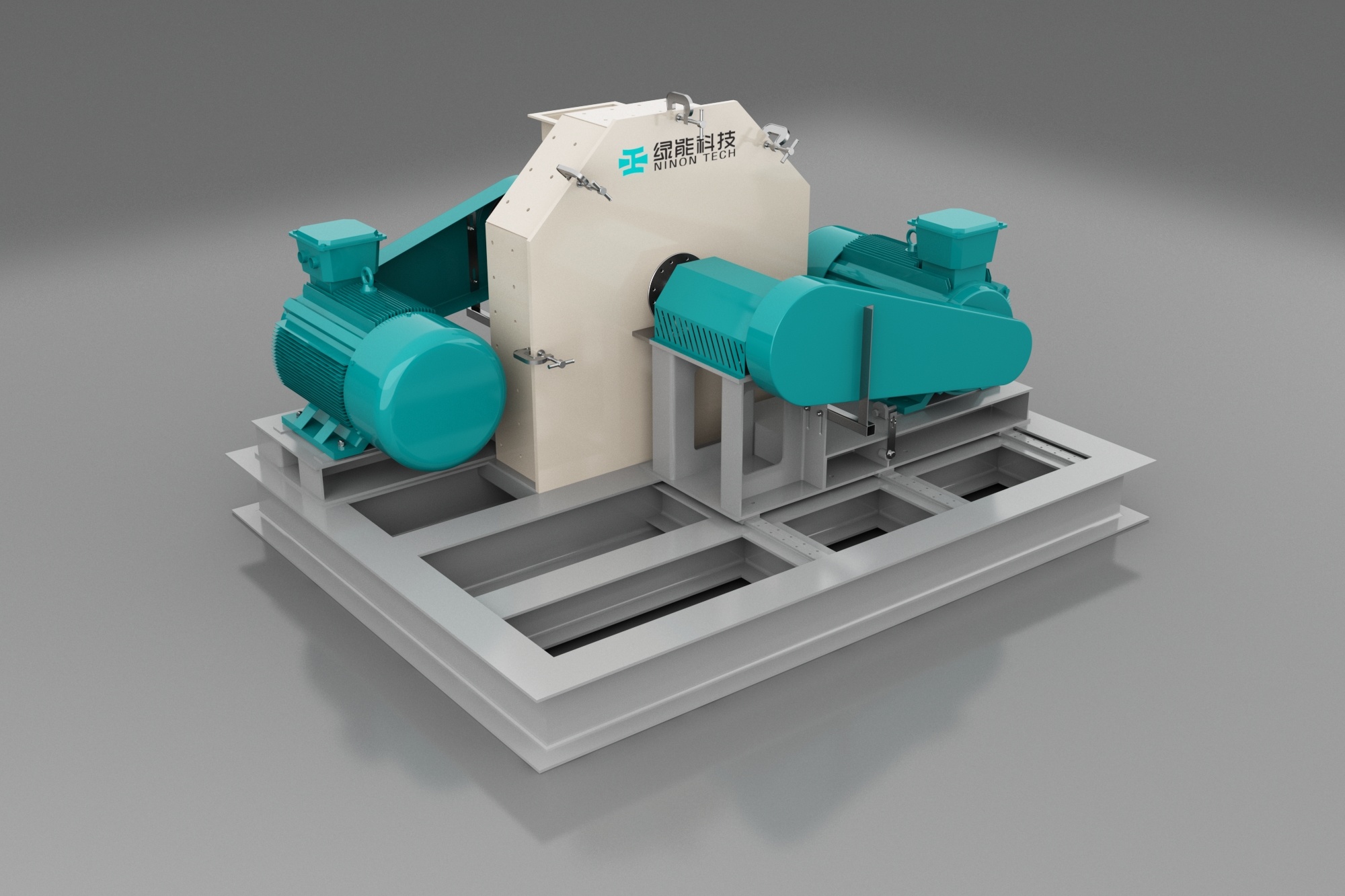

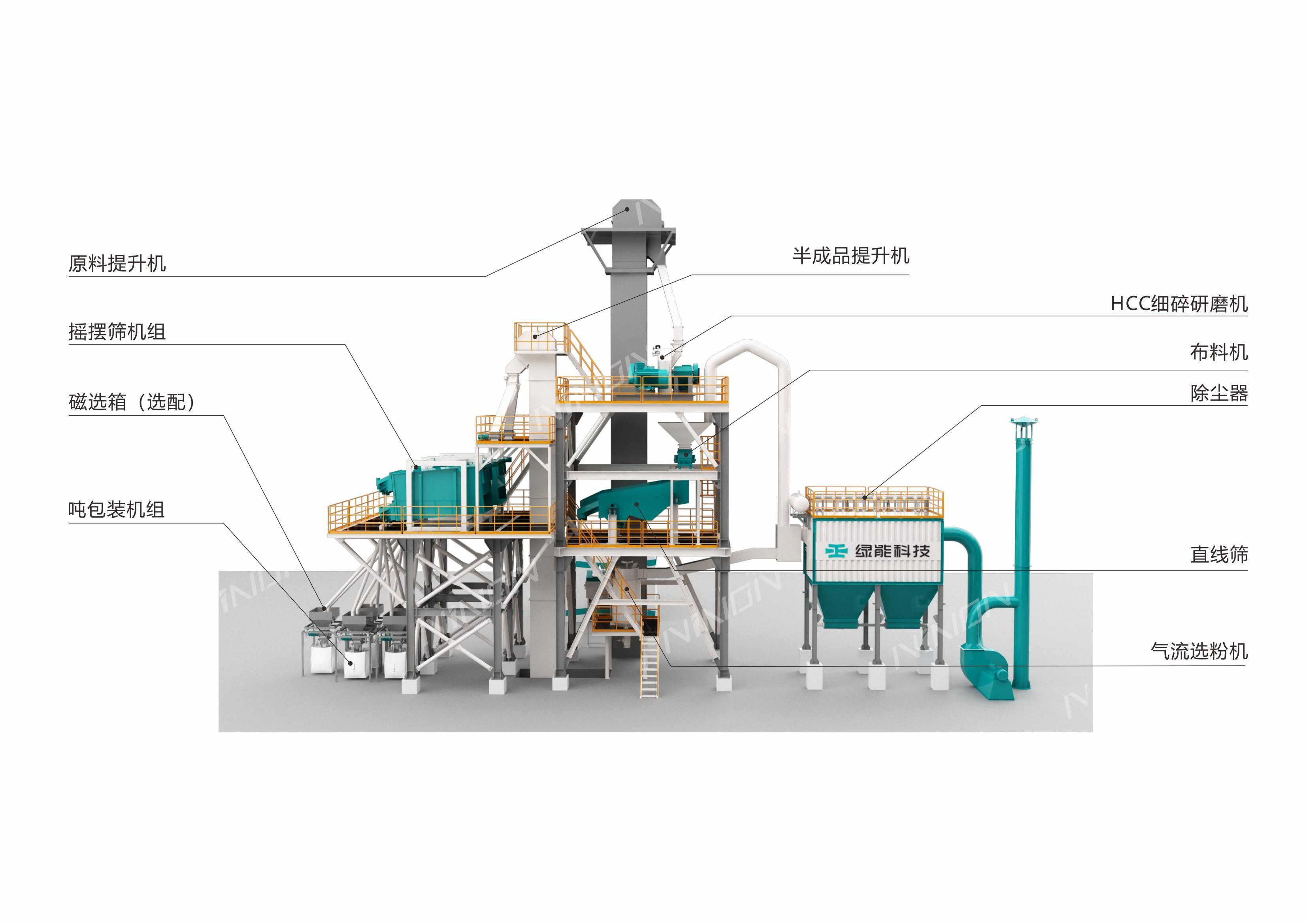

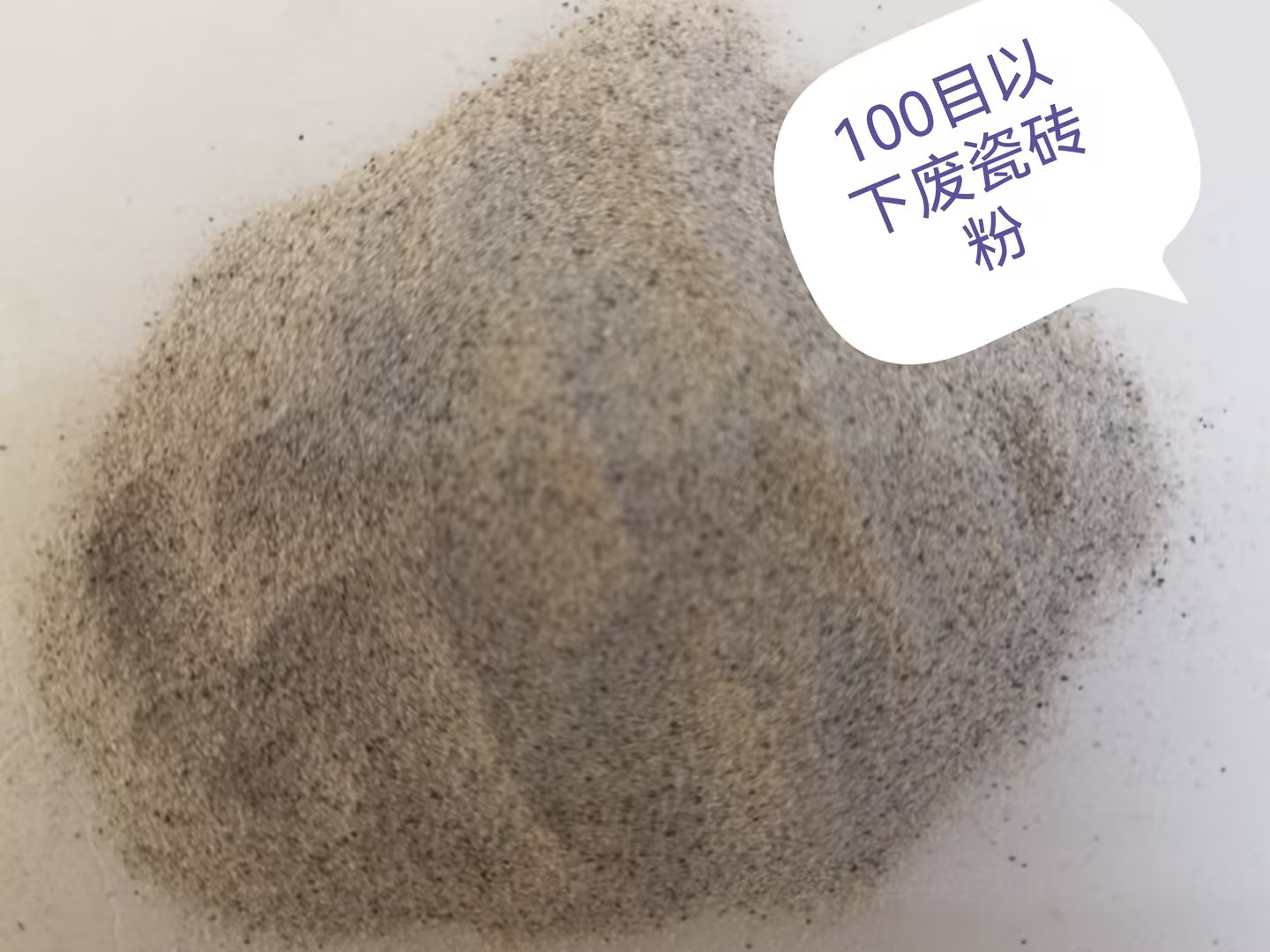

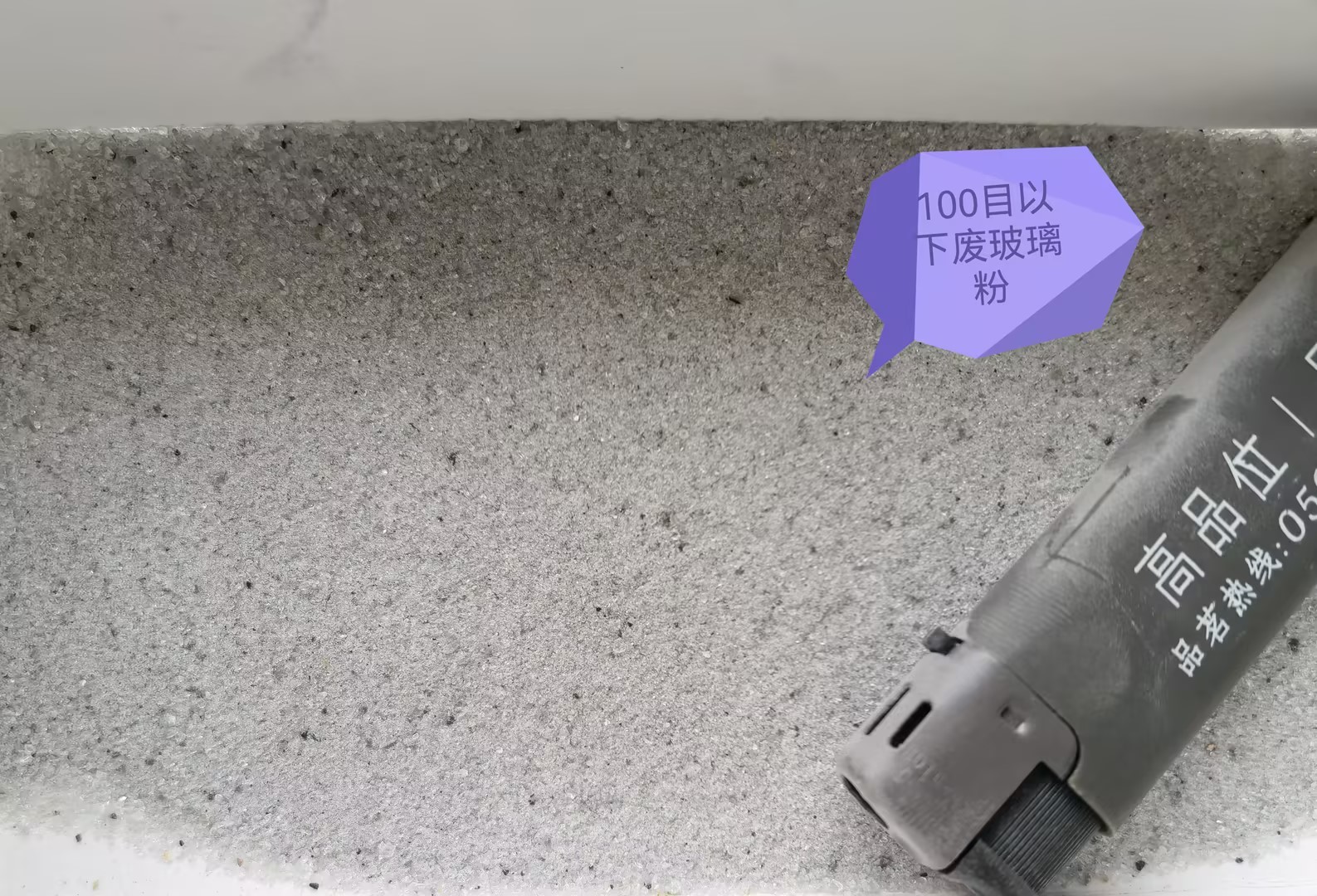

This equipment is suitable for: quartz sand, foundry sand, fracturing sand, special mortar sand, glass sand and proppant, asphalt mortar and other industries,Based on the technological upgrading and industrial upgrading of the industry, higher requirements are put forward for raw materials (sand): higher requirements are put forward for purity, fineness, strength, PSD, shape, etc. Based on this, our company has developed fine HCC grinding equipment, fine screening equipment (high frequency, pendulum, air flow screen), HMW scrubbing equipment and fine sand fine screening complete sets of equipment. Generally divided into (20-40-70-120-200 mesh), the equipment according to the site needs, can be designed for plane structure or building station structure.

The basic process flow is as follows

1. Crushing (paragraph 1-2)-powder and impurity removal, iron removal-separation-purification (flotation, gravity separation, pickling, etc.)-drying (if necessary)-packaging of finished products will vary according to different materials and requirements

2. Before grading, the raw materials should be dry (less than 0,3%) and free of powder (generally less than 0.5) except impurities.

3. The equipment structure can be designed as tiled or tower station structure according to the site.

Major Breakthroughs:

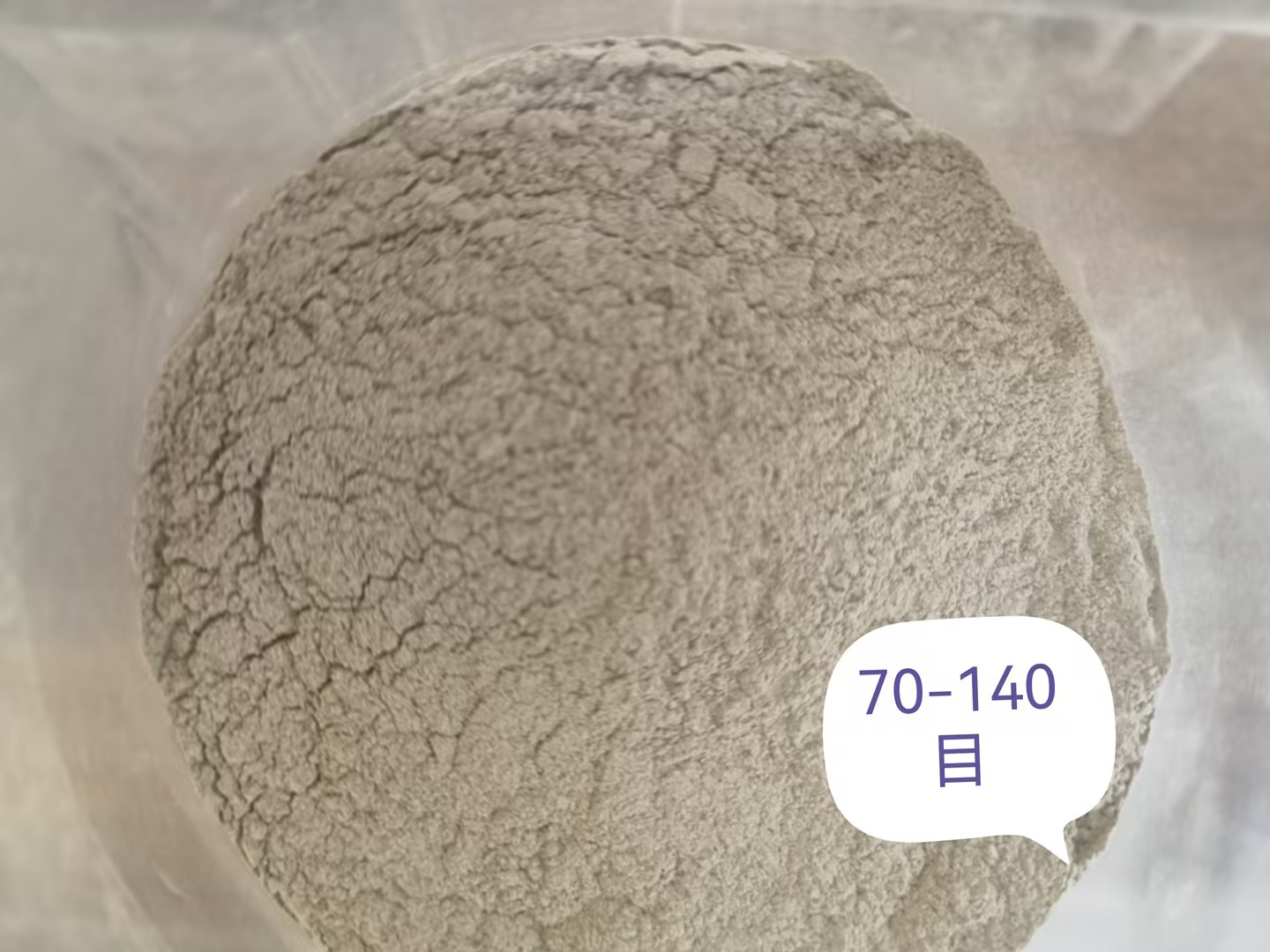

>>HCC fine grinding machine can perfectly carry out sand making with wet materials (standard sand and fine sand) after factory material carrying test. it can meet the grading requirements at one time and the powder content (-200 mesh) is reduced by 20-40% (general content is about 4-7%) compared with vertical shaft breakage and has very little dust on site. Test results: granite 20mm feed, can be one-time production of two-zone graded medium sand, one-time 0,8mm-0.12mm(20 mesh -140 mesh) below the yield ratio can reach 70-80%, energy consumption is only 60-70% of the impact crusher, energy saving and consumption is obvious,. This is a great innovation. Aiming at the current dry and wet sand making processes, it has great breakthroughs (production capacity, energy consumption, powder content, process complexity, etc.). The process is simple, the area is small, and the investment in environmental protection is low. The equipment cost is also greatly reduced (dry dust removal, powder selection system, wet water washing and dehydration system, etc. can be omitted) and the economy is greatly improved, and it has strong competitiveness and cost performance.

In particular, it solves the problem of moisture content of raw materials and the utilization of stone powder, which are the most troublesome problems in dry sand production.

This machine can be widely used in fine sand, quartz sand, glass, ceramics, foundry sand, clay and other mineral materials.

>> subversion regular mode, new sand (powder) mode, unparalleled advantage! (Can replace the primary mill to prepare 200-400 mesh powder)

Pictures of field cases

Related Products

undefined

Product Message

Tik Tok

Fujian Green Energy Environmental Protection Technology Co., Ltd.

Service Hotline:4006655896

Tel:0595-22557155、13808548004

Email:nonnon@fjlnkj.com

Website:http://www.fjlnkj.com/

Factory Address: Hardware and Electromechanical Industrial Park, Luojiang Economic Development Zone, Quanzhou City, Fujian Province (No. 268, Luobin North Road)

Page Copyright © 2022 Fujian Green Energy Environmental Protection Technology Co., Ltd.